Mechanical engineering involves a group of disciplines also known as branches where we can find thermo-systems, manufacturing and design. Talking about the latter, we can say is the branch where the engineer can combine a series of components to create a new element or machine which shall be manufactured in a future. In order to achieve such creation, the engineer must go through very detailed calculation to determine the best components for the purpose of the design. A very important part of this entire process are the fasteners, which allow us to join together different parts or components and also make sure they will not have any undesirable movement while in service.

There are different types of fasteners with specific properties and uses, which should be selected according to the application. Among them, we find bolts, nuts and grub or set screws as the most common ones.

Let’s get to know a little more about the fasteners that were mentioned above.

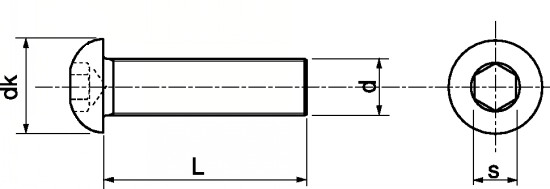

Bolts

First of all, the use of the words “bolt” and “screw” is widely unclear and the difference commonly misunderstood. A good way to have a better idea on this matter is that a bolt is described as any threaded fastener that is used together with a nut in order to assembly two unthreaded components, and that a screw is described as the same threaded fastener, but in this case being used to assembly two components where one of them has an internal thread where the fastener is fitted. Now, you can be sure that every time you use a bolt you will be needing a nut to complete what is known as a bolted joint. In this type of joint, the nut provides a fastening axial force at the time the bolt provides the needed resistance against shear forces.

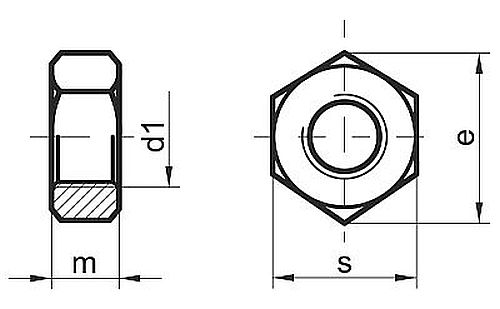

Nuts

As mentioned before, the nut is the element providing the fastening force in a bolted joint. The main feature of its structure is the threaded hole where the bolt is fitted, and its profile can be squared or hexagonal, being the latter the most common one. The bolted joints are frequently used because many applications makes it difficult to have a threaded hole in one of the parts being assembled. However, there are applications that involve a lot of movement and vibrations which can get the nut loose; thus, creating a major problem. This kind of problems are solved by adding other locking mechanisms.

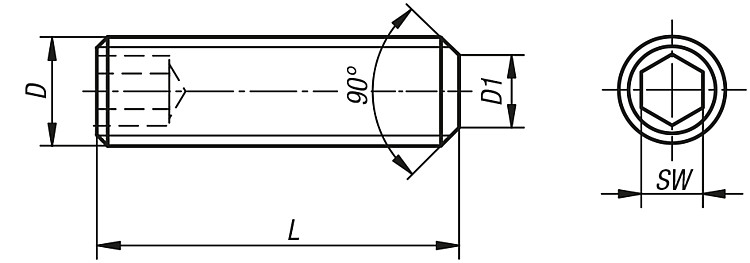

Grub or Set Screws

Also known as “blind” set screws, this type differs from the rest for not having a head, but only a hole with a specific shape which suggests the type of tool that should be used in order to drive it. The most common ones are hexagonal (Allen), squared (Robertson) and star shaped (Torx). This kind of screw are frequently used as “safety” holders, together with a detent in order to resist or transmit high torque, which is why they are used in applications where parts are attached to a shaft, such as couplings, bearings, pulleys, among others.