Fasteners are a key element in everyday life. They are present in any structure or device in order to hold their parts working together.

In the automobile industry, this key elements take a higher level of importance, since they form part of important systems which involve the security of the driver and its passengers.

Some of the critical systems where fasteners are frequently selected and used very carefully and with a very demanding criteria are: security systems, electrical mounting, brake systems, airbags, fluid carrying components, transmission components, among others.

Among the most common fasteners used in the automobile industry, there are bolts, nuts, studs, washers, screws, rivets and tie rods.

Let’s take a closer look to each one of them.

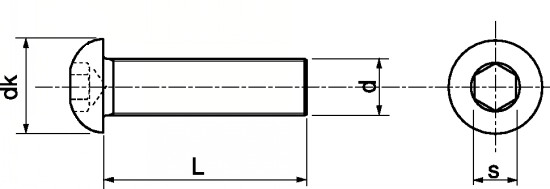

Bolts

They comprise a threaded pin or a threaded rod and a head at one end, and they need a matching nut in order to fulfill their function.

In the automobile industry, the most important ones are the engine mounting bolts, the suspension bolts and the connecting rod bolts.

Being such a dedicated industry, with many specialized systems, these bolts are normally fabricated according to the cars manufacturer specs. However, the most common materials used are steels, ranging strengths that can reach the 1500 MPa.

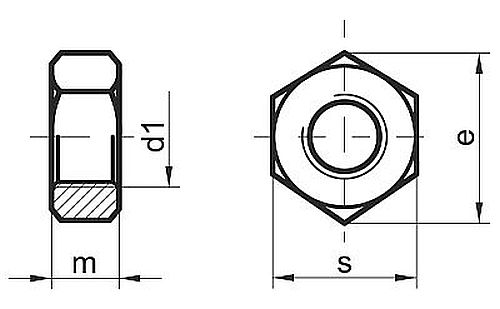

Nuts

As mentioned in the previous point, these are the complement for the bolts. Again, there are different types according to their function, such as hex nuts, plate nuts and self-locking nuts.

The material requirements of these elements for their use in automotive and related industries are mainly covered by the standards SAE J482 and ASME B18.2.2, although they normally match the material of the corresponding bolt.

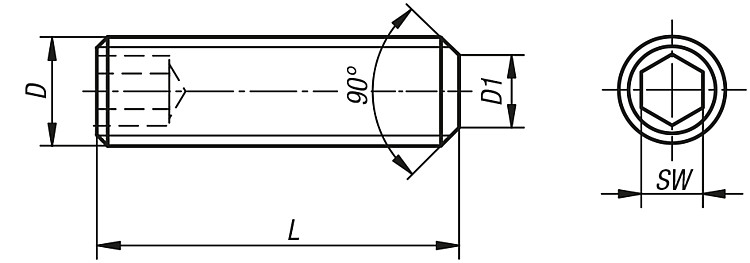

Studs

These type of fasteners are mainly used in the engine and wheels systems. There are different materials, being those made of stainless steel the most common ones. However, due to the different needs from cars manufacturers, there are also brass studs, copper studs, aluminum studs and even plastic studs among others.

The way they work is by being fastened at both ends with an unthreaded shank.

Washers

Although they do not look as important as the rest of the elements, they really are. Just to mention one of their important functions, they can prevent leakage which is a very important aspect in the automobile industry.

The most relevant ones are known by the name of the system where they are used, such as the cylinder head washers and the radiator washers (here’s the leakage prevention importance mentioned before).

Screws

They are very similar to bolts, with the difference that they do not need the use of a nut. Normally, they are used to hold to parts which are already threaded in order to match with the screw. Furthermore, some of the screws used in the automobile industry can be driven through some materials without deforming or breaking. These are called tapping screws.

Rivets

Considered one of the oldest fastener in the industry it is being used across a wide range of applications.

They are very fast and easily placed which makes them a good option for a high paced industry as the automobile one. However, it is important to select it correctly according to the application in order to ensure its correct operation. A good practice to achieve the best results would be checking SAE J492 standard which comprises a complete guide for rivet selection and design consideration.

Tie rods

Their main use lies on the steering system. There, they are used to join the pitman arm and the idler arm to the steering knuckle arms. Having a flexible coupling at the end, they are able to turn the wheels with the force coming from the rack gear to the steering knuckle.

Since all of these elements are so important for the correct operation and smooth performance of the systems mentioned before, the general recommendation is to use those parts which are certified under the international standards.

(photo sources: wikipedia.org and pixabay.com)

Staqoo Virginia Products